The relentless pursuit of efficiency and productivity is perpetually reshaping industries and daily life. As technology advances at an unprecedented pace, the tools we use are becoming smarter, more integrated, and increasingly autonomous. This is the era of future automation gear, a groundbreaking evolution of digital and physical instruments designed to unleash unparalleled efficiency across every domain. Far from simply automating repetitive tasks, these next-generation tools leverage artificial intelligence, advanced robotics, and seamless connectivity to augment human capabilities, predict needs, and optimize complex workflows. This isn’t just about incremental improvements; it’s a revolutionary leap towards a future where efficiency isn’t just a goal, but an inherent quality, truly unleashed now.

The Evolution of Tools: From Manual to Autonomous

To fully grasp the transformative power of future automation gear, it’s essential to trace the historical progression of tools, understanding how we’ve moved from basic manual implements to the sophisticated, intelligent systems of today.

A. The Dawn of Manual and Mechanical Tools

For millennia, human progress was defined by our ability to craft and utilize tools to extend our physical capabilities.

- Simple Hand Tools: Early tools like hammers, levers, and knives augmented human strength and dexterity, allowing us to build, hunt, and cultivate more effectively. These required direct human effort and skill for every action.

- Mechanical Augmentation: The Industrial Revolution introduced mechanical tools and machinery. Water and steam power, then electricity, drove looms, presses, and assembly lines. These tools multiplied human output but still required significant human oversight, manual adjustments, and lacked true decision-making capability.

- Limitations of Early Automation: While these mechanical tools revolutionized production, they were rigid and single-purpose. Reconfiguring a factory floor for a new product was a massive undertaking. Errors required manual intervention, and there was little to no real-time feedback or self-optimization.

B. The Digital Revolution and Software Tools

The advent of computing transformed tools from physical machines to intangible software. This brought unprecedented levels of speed, precision, and the ability to process information.

- Productivity Software: Early computers gave us word processors, spreadsheets, and databases, digitizing office work and speeding up calculations. These were fundamentally about automating information processing, but still heavily reliant on human input and instruction.

- Specialized Design Tools: CAD (Computer-Aided Design) software revolutionized engineering and architecture, allowing complex designs to be created and modified with ease. Simulation tools enabled virtual testing, but these were largely offline processes.

- Early Automation Scripts: Basic scripting and batch processing allowed for rudimentary automation of digital tasks. However, these scripts were rigid, required explicit instructions for every step, and lacked adaptability to changing conditions.

- Rise of the Internet: The internet brought connectivity, enabling collaborative tools and remote access, breaking down geographical barriers for teamwork. But the intelligence within these tools remained primarily reactive to human commands.

C. The Era of Intelligent Automation: Leading to Future Gear

The confluence of powerful computing, vast data availability, and breakthroughs in Artificial Intelligence has propelled us into the age of intelligent automation, setting the stage for the future of tools.

- Machine Learning Integration: Tools began to ‘learn’ from data, identifying patterns and making predictions. This moved automation beyond simple rules to adaptive, data-driven decisions (e.g., spam filters, recommendation engines).

- Robotics in Controlled Environments: Industrial robots became common in manufacturing, performing repetitive tasks with high precision in controlled environments. These were largely pre-programmed and less adaptable to variability.

- Sensor Proliferation: The Internet of Things (IoT) vastly expanded the reach of sensors, allowing real-time data collection from the physical world, feeding intelligence into digital systems.

- Rise of Cloud Computing: Cloud platforms provided the scalable infrastructure needed to process vast amounts of data and host complex AI models, making advanced automation accessible to more organizations.

This progression highlights a consistent trend: tools are becoming less reliant on explicit human instructions and more capable of autonomous operation, learning, and optimization, culminating in the “future automation gear” we see emerging today.

Core Pillars of Future Automation Gear

The next generation of automation tools isn’t just about standalone gadgets; it’s about integrated systems built upon several foundational technological pillars.

A. Artificial Intelligence and Machine Learning (AI/ML)

At the very heart of future automation gear is Artificial Intelligence, particularly Machine Learning (ML). AI transforms tools from reactive implements to proactive, intelligent agents.

- Predictive Analytics: AI allows tools to analyze historical and real-time data to predict future outcomes (e.g., predicting equipment failure before it happens, forecasting market trends for business tools). This shifts operations from reactive to proactive.

- Adaptive Learning: Tools can learn from ongoing interactions and data, continually improving their performance and adapting to new situations without explicit reprogramming. This is crucial for navigating dynamic environments.

- Natural Language Processing (NLP) and Generation (NLG): AI-powered tools can understand and generate human language, enabling intuitive voice commands, automated content creation, and sophisticated chatbot interactions, making human-tool interaction more seamless.

- Computer Vision: Robots and smart cameras use computer vision to perceive and interpret their surroundings, allowing for automated quality control, object recognition, and navigation in complex environments.

- Generative AI: Beyond analysis, generative AI can create new content, designs, or code, greatly accelerating creative and development processes (e.g., AI-assisted architectural design, automated marketing copy).

B. Robotics and Advanced Actuation

While AI provides the ‘brain,’ robotics and advanced actuation provide the physical capability for intelligent tools to interact with the real world.

- Collaborative Robots (Cobots): Designed to work safely alongside humans, cobots handle repetitive or heavy tasks, augmenting human capabilities without replacing them entirely. They are equipped with advanced sensors for collision avoidance.

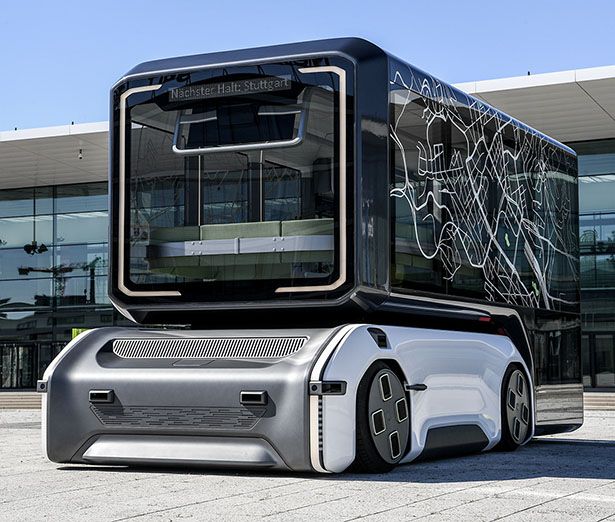

- Autonomous Mobile Robots (AMRs): Unlike traditional AGVs (Automated Guided Vehicles) that follow fixed paths, AMRs use AI and sensors to navigate dynamic environments, delivering materials or performing inspections autonomously (e.g., in warehouses, construction sites).

- Dexterous Manipulation: Advances in robotic grippers and manipulation capabilities allow robots to handle delicate, irregularly shaped, or small objects with increasing precision and adaptability, expanding their use beyond rigid manufacturing lines.

- Soft Robotics: Utilizing compliant materials, soft robots can adapt their shape to interact safely with fragile objects or navigate complex, constrained spaces, opening new avenues in healthcare and logistics.

C. Internet of Things (IoT) and Ubiquitous Connectivity

The proliferation of connected sensors and devices forms the nervous system of future automation, providing the data necessary for intelligent operation.

- Real-time Data Streams: IoT sensors embedded in tools, machinery, and environments constantly feed vast amounts of real-time data (e.g., temperature, pressure, vibration, location, usage patterns) to central processing units.

- Edge Computing: Processing data closer to the source (at the ‘edge’ of the network) reduces latency and bandwidth requirements, enabling faster decision-making for critical, time-sensitive automated tasks (e.g., autonomous vehicles, industrial control).

- 5G and Beyond: High-speed, low-latency wireless networks (like 5G) are crucial for supporting massive numbers of connected devices and facilitating real-time communication between autonomous tools and centralized intelligence, enabling complex collaborative tasks.

- Digital Twin Integration: IoT data feeds into Digital Twins—virtual replicas of physical assets—allowing for real-time monitoring, simulation, and predictive analysis, providing a comprehensive operational overview for automation.

D. Cloud Computing and Distributed Systems

The sheer computational power and storage required for complex AI models and vast IoT data streams are provided by scalable cloud infrastructure.

- Scalable Data Processing: Cloud platforms offer elastic compute and storage, capable of handling the immense data volumes generated by automated tools and the heavy processing demands of AI/ML models.

- Centralized Intelligence: Complex AI models and global optimization algorithms can reside in the cloud, processing data from numerous distributed tools and sending back optimized commands.

- Global Collaboration: Cloud-based tools enable geographically dispersed teams to collaborate seamlessly on automated projects, accessing shared data and models from anywhere.

- Software-as-a-Service (SaaS) Models: Many advanced automation tools are delivered as SaaS, reducing upfront costs and ensuring continuous updates and scalability for users.

Transformative Advantages of Future Automation Gear

The synergistic application of these core pillars unlocks a multitude of profound benefits, fundamentally reshaping how businesses operate and how individuals interact with their environment.

A. Unprecedented Efficiency and Productivity Boosts

The primary driver for future automation gear is the dramatic increase in efficiency and overall productivity.

- Elimination of Repetitive Tasks: Intelligent tools fully automate mundane, repetitive, and time-consuming tasks across industries (e.g., data entry, inventory management, customer support, certain manufacturing processes), freeing up human workers for more complex and creative endeavors.

- Optimized Workflows: AI-powered tools can analyze vast datasets to identify inefficiencies in workflows, recommend optimal sequences, and even autonomously reconfigure processes for maximum output, leading to leaner operations.

- Continuous Operation: Unlike humans, automated systems do not fatigue, require breaks, or get sick. This allows for continuous, 24/7 operation in many scenarios, significantly increasing throughput and utilization of assets.

- Resource Optimization: Intelligent tools can precisely manage resource consumption (e.g., energy, raw materials, time), minimizing waste and leading to substantial cost savings and a reduced environmental footprint.

B. Enhanced Precision and Unwavering Quality

Automated systems can perform tasks with a level of accuracy and consistency that far surpasses human capabilities, leading to superior quality outputs.

- Sub-millimeter Accuracy: Robots and automated machines can execute tasks (e.g., drilling, cutting, assembly) with extreme precision, ensuring tight tolerances and consistent product quality across large production runs.

- Reduced Errors and Rework: By eliminating human error in repetitive tasks, automation drastically reduces defects and the need for costly rework, leading to higher first-pass yield and improved customer satisfaction.

- Automated Quality Control: Tools equipped with computer vision and other sensors can perform continuous, real-time quality inspections, identifying anomalies or defects immediately in the production process, preventing flawed products from reaching the market.

- Standardized Output: Regardless of operator skill level or fatigue, automated tools ensure a standardized output, crucial for maintaining brand reputation and meeting regulatory compliance.

C. Significant Improvement in Safety and Risk Mitigation

Automating hazardous or physically demanding tasks inherently transforms workplace safety.

- Removal of Humans from Danger Zones: Robots can perform tasks in dangerous environments (e.g., extreme temperatures, hazardous chemicals, confined spaces, high-pressure situations, heavy lifting), removing human workers from exposure to injury or harm.

- Reduced Repetitive Strain Injuries: Tasks that lead to long-term ergonomic injuries for human workers can be assigned to robots, improving worker health and reducing worker compensation claims.

- Predictive Safety: AI-powered tools can monitor equipment health and operational conditions to predict potential safety hazards (e.g., machinery breakdown, abnormal readings) and issue proactive warnings, allowing for preventative action.

- Controlled Operations: Automated systems operate within defined parameters, reducing the likelihood of accidents caused by human error, fatigue, or inexperience, leading to a more predictable and safer operational environment.

D. Unleashing Innovation and Creative Potential

By taking over the mundane, future automation gear empowers humans to focus on higher-value activities.

- Focus on Creativity and Strategy: When repetitive tasks are automated, human talent can be redirected towards complex problem-solving, strategic planning, innovation, and creative endeavors that require uniquely human cognitive abilities.

- Rapid Prototyping and Iteration: Generative AI tools can quickly produce design variations, code snippets, or content drafts, accelerating the prototyping and iteration cycles in product development and design.

- Personalized Experiences: Automation enables the delivery of highly personalized products, services, and experiences at scale, from customized learning paths to tailored marketing campaigns, enriching user engagement.

- New Business Models: The capabilities unlocked by advanced automation can lead to entirely new business models, service offerings, and competitive advantages, driving economic growth and societal progress.

Navigating the Challenges of Adopting Future Automation Gear

Despite its immense promise, the widespread adoption of future automation gear faces several significant challenges that organizations must carefully navigate and strategic policy-makers must address.

A. High Initial Investment and Complex ROI Calculation

Acquiring sophisticated AI-powered software, advanced robotic systems, and the necessary integration infrastructure can represent a substantial upfront capital expenditure. For many businesses, particularly Small and Medium-sized Enterprises (SMEs), this constitutes a significant financial hurdle. Furthermore, accurately calculating the Return on Investment (ROI) can be complex, as benefits often extend beyond direct cost savings to include intangible gains like improved safety, higher quality, and enhanced brand reputation, which are harder to quantify.

B. Technical Complexity and Integration Expertise

Implementing and maintaining highly automated, intelligent systems requires deep technical expertise. Integrating disparate systems, managing vast data streams from IoT devices, training complex AI/ML models, and ensuring interoperability between various hardware and software components demands specialized skills that are currently in high demand. The technical complexity often necessitates hiring new talent or investing heavily in reskilling existing teams.

C. Workforce Transformation and Ethical Concerns

The most significant societal challenge is the impact on the workforce. While automation creates new jobs (e.g., robot technicians, AI trainers, data scientists), it will inevitably displace workers performing routine or manual tasks. This raises serious ethical concerns about job displacement, income inequality, and the need for massive reskilling and upskilling initiatives. Managing this transition equitably and ensuring a just transition for affected workers is paramount to avoid social unrest.

D. Data Quality, Privacy, and Cybersecurity Risks

Future automation gear is inherently data-driven. The effectiveness of AI models relies heavily on the quality, quantity, and ethical sourcing of data. Biased or incomplete data can lead to flawed automation. Moreover, collecting and processing vast amounts of operational and personal data raises significant privacy concerns and creates new cybersecurity vulnerabilities. Protecting these interconnected systems from malicious attacks and ensuring data integrity is a continuous, complex challenge.

E. Lack of Standardization and Interoperability

The automation landscape is currently fragmented, with many proprietary systems and a lack of universal standards for communication and interoperability between different vendors’ hardware and software. This makes it challenging to integrate diverse components into a cohesive automation ecosystem, leading to vendor lock-in and inhibiting the seamless exchange of data and commands across different automated tools.

F. Regulatory Frameworks and Legal Liability

Existing regulatory frameworks and legal precedents were largely established before the advent of highly autonomous systems. This creates a vacuum in areas such as legal liability for accidents involving autonomous robots (who is responsible?), data governance, and the ethical use of AI. Governments and international bodies are grappling with the need to develop new, agile regulations that foster innovation while ensuring public safety and accountability.

G. Resistance to Change and Cultural Adoption

Beyond technical hurdles, human factors play a critical role. Resistance to change from employees fearing job loss or discomfort with new technologies can significantly impede adoption. Companies must foster a culture that embraces continuous learning, values human-robot collaboration, and champions the long-term benefits of automation. Effective change management, transparent communication, and genuine employee involvement are crucial.

H. Energy Consumption and Environmental Impact

While some forms of automation can lead to energy efficiency, the sheer computational power required for advanced AI and vast IoT networks can also lead to significant energy consumption. As automation becomes more pervasive, managing its environmental footprint and ensuring that the pursuit of efficiency doesn’t exacerbate energy crises becomes an important ethical and practical consideration, requiring investment in green computing and sustainable power sources.

Best Practices for Implementing Future Automation Gear

To successfully integrate future automation gear and unlock its profound benefits, organizations must adopt a strategic, phased, and human-centric approach, focusing on preparation, people, and continuous optimization.

A. Define Clear Strategic Objectives and Start Small

Before embarking on a large-scale automation initiative, clearly define the strategic business objectives you aim to achieve (e.g., reduce specific operational costs, improve product quality, enhance safety in a particular area). Identify high-impact, low-risk pilot projects where automation can demonstrate clear, measurable value quickly. This incremental approach allows for learning, builds internal champions, and provides tangible ROI to justify further investment, avoiding a ‘big bang’ failure.

B. Invest Heavily in Workforce Upskilling and Training

Recognize that future automation gear augments, rather than simply replaces, human capabilities. Prioritize comprehensive workforce upskilling and reskilling programs. Train existing employees in new roles such as robot operation, maintenance, programming, AI model monitoring, data analytics, and human-robot collaboration. Foster a culture of continuous learning and embrace a ‘human-in-the-loop’ approach, where humans supervise and troubleshoot automated systems, becoming critical decision-makers and innovators. Transparent communication about job evolution is key.

C. Prioritize Data Infrastructure and Quality

Data is the fuel for intelligent automation. Invest in robust data infrastructure capable of collecting, storing, processing, and analyzing vast amounts of real-time data from automated tools and IoT devices. Implement strong data governance practices to ensure data quality, consistency, and security. Clean, accurate, and relevant data is paramount for training effective AI models and driving reliable automation. Consider data lakes, streaming platforms, and secure cloud storage.

D. Embrace a Phased Implementation and Iterative Development

Treat automation projects like software development, using agile methodologies. Implement solutions in phases, starting with simple automation and gradually increasing complexity. Encourage iterative development, where solutions are continuously refined based on feedback from pilots and real-world performance data. This allows for flexibility, adaptability, and the ability to course-correct based on new insights or evolving requirements.

E. Focus on Interoperability and Open Standards

Where possible, prioritize interoperability and solutions that adhere to open standards. This reduces vendor lock-in, facilitates integration between different types of automated tools and software, and allows for greater flexibility in building a cohesive automation ecosystem. Consider common communication protocols, data formats, and API standards to ensure seamless data exchange across your automated tools.

F. Implement Robust Security and Governance from Day One

Given the interconnected nature and potential real-world impact of automated systems, security and governance must be foundational. Implement end-to-end encryption for data, enforce strict access controls (least privilege), and develop comprehensive cybersecurity strategies to protect all components of your automation infrastructure. Establish clear governance policies for data privacy, ethical AI use, and compliance with relevant industry regulations (e.g., GDPR, HIPAA, industry-specific safety standards). Regular security audits are essential.

G. Cultivate a Culture of Innovation and Experimentation

For organizations to truly thrive with future automation gear, they must foster a culture that embraces innovation, experimentation, and continuous improvement. Encourage cross-functional teams to explore new automation possibilities, allocate resources for R&D and pilot programs, and be willing to learn from both successes and failures. This adaptive mindset is crucial for staying competitive in a rapidly evolving technological landscape.

H. Design for Resilience and Fault Tolerance

Automated systems must be resilient. Design solutions with built-in fault tolerance and redundancy. Implement monitoring and alerting systems to detect failures rapidly. Develop automated recovery mechanisms (e.g., failovers, self-healing capabilities). Ensure that the failure of one automated component does not lead to a cascading failure of the entire system. Consider ‘human-in-the-loop’ systems where human oversight can take over in complex or unexpected failure scenarios.

I. Measure, Monitor, and Optimize Continuously

The true value of future automation gear comes from continuous improvement. Implement comprehensive monitoring and analytics to track the performance of your automated systems (e.g., efficiency gains, error rates, uptime, resource consumption). Use this data to identify bottlenecks, opportunities for further optimization, and areas where AI models can be retrained for better performance. This data-driven approach ensures ongoing value creation.

J. Address Ethical and Societal Impacts Proactively

Engage with stakeholders, employees, and policymakers to address the broader ethical and societal implications of automation. Develop internal ethical guidelines for AI use. Contribute to industry discussions on responsible automation. Plan for social safety nets and retraining programs for workers whose roles are displaced. A proactive and responsible approach to these issues is crucial for sustainable adoption.

The Future Trajectory of Automation Gear

The trajectory of automation gear is one of increasing intelligence, autonomy, and integration, promising to redefine not just industries but the very fabric of our daily lives.

A. Hyper-Personalization and Adaptive Tools

Future automation gear will move beyond generalized solutions to deliver hyper-personalized and adaptive experiences. AI will enable tools to understand individual user preferences, work styles, and needs, automatically adjusting interfaces, suggesting optimal workflows, and tailoring assistance (e.g., AI assistants that truly understand your context, adaptive learning platforms that optimize content for each student).

B. Autonomous Operations and Self-Organizing Systems

The long-term vision is towards truly autonomous operations where entire systems are self-organizing and self-optimizing. Factories could largely run themselves, smart cities could dynamically manage traffic and energy, and logistics networks could adapt to real-time disruptions without constant human oversight. This will require advanced swarm intelligence among robotic units and highly robust AI decision-making.

C. Human-AI Symbiosis and Augmented Intelligence

The future isn’t about humans vs. machines, but human-AI symbiosis. Future automation gear will act as powerful augmenters of human intelligence, helping us process vast information, make better decisions, and unleash unprecedented creativity. Tools will predict our next steps, offer intelligent suggestions, and handle cognitive burdens, allowing humans to focus on higher-level strategic thinking, empathy, and innovation.

D. Pervasive Robotics and Physical Automation

Robots will become more commonplace outside of controlled factory environments. We’ll see more pervasive robotics in logistics, construction, healthcare, agriculture, and even homes. These robots will be more dexterous, capable of navigating unstructured environments, and seamlessly collaborating with humans, taking on more diverse physical tasks.

E. Sustainable Automation and Circular Economy Integration

Future automation gear will increasingly be designed with sustainability at its core. This includes:

- Energy-Efficient AI Hardware: Development of more energy-efficient chips (e.g., neuromorphic, optical) to power AI.

- Resource Optimization: Tools that precisely manage material usage, reduce waste, and optimize energy consumption in production and operations.

- Circular Economy Enablers: Robots capable of disassembling products for recycling, sorting materials, and performing precision repairs to extend product lifespans, directly supporting circular economy principles.

F. Global Interconnected Automation Ecosystems

The rise of global, interconnected automation ecosystems will transform supply chains, logistics, and collaborative projects. Autonomous tools and systems from different organizations and geographical locations will seamlessly exchange data and coordinate actions, enabled by standardized protocols and robust cloud/edge infrastructure, creating a truly global web of efficiency.

Conclusion

The evolution of tools has been a defining characteristic of human civilization, constantly pushing the boundaries of what’s possible. Today, we stand at the precipice of a new era, one defined by future automation gear – intelligent, connected, and increasingly autonomous instruments that are poised to unleash unprecedented levels of efficiency. This transformation extends far beyond simply automating tasks; it’s about fundamentally reshaping industries, optimizing complex systems, and profoundly augmenting human potential.

While the journey towards this automated future presents significant challenges in terms of investment, technical integration, and workforce adaptation, the compelling advantages it offers in terms of productivity, precision, safety, and innovation are simply too profound to ignore. By embracing strategic planning, investing in workforce upskilling, prioritizing data quality and security, and fostering a culture of continuous learning and ethical development, organizations can navigate this transition successfully. The future is not just about having the best tools; it’s about having the smartest, most collaborative, and most efficient automation gear, unlocking a new era of possibilities and truly unleashing efficiency now.